BioPRIA researchers have conducted comprehensive research on cellulose nanomaterials, spanning production, characterization, and application.

Characterization

A novel method called the gel-point method has been developed to estimate the aspect ratio of nanofibers. This method determines the lowest solids concentration at which a suspension forms a continuous network, which is particularly challenging for visualizing cellulose nanofibers due to their high aspect ratio. Warren Batchelor, the chair of the Standards Australia committee, is actively involved in developing industry standards for cellulose nanomaterials through the worldwide committee PK-019.

Production

The high cost and energy consumption have been significant barriers to the commercialization of cellulose nanomaterials. BioPRIA researchers have investigated scale-up efficiencies and demonstrated an 80% improvement in energy consumption during the transition from laboratory to industrial-scale production through refining. Innovative methods such as selective separation with flotation have also been explored to enhance energy efficiency by generating a fines-rich stream that can be readily converted into cellulose nanofibers.

Application

One major challenge in applying cellulose nanomaterials, even at the lab scale, has been the production of cellulose nanomaterial films. However, BioPRIA researchers have developed a spray coating method that enables the production of hundreds of films in a batch. This method allows for spraying at higher solids content compared to conventional vacuum forming, leading to significantly reduced drying time.

BioPRIA researchers have successfully produced sprayed films using various cellulose nanomaterials, including different types of cellulose nanofibrils (CNF) and cellulose nanocrystals (CNC). They have also focused on creating composites by incorporating other materials such as exfoliated clays and sugars to enhance properties like water vapor transmission rate and barrier properties.

RESEARCH PROJECTS

Creation of micropatterned nanocellulose films for high value applications

We create micropatterned nanocellulose films 1-3 with the spray coating method developed in our group. We have achieved a minimum feature of a 5 µm wide and 6 µm deep channel. The fidelity of the micropatterns can be manipulated to create surfaces with large variation in water droplet contact angles along with directing fluid flow. These films have great potential in the areas of microfluidic devices and paper-based diagnostics.

Characterisation of cellulose nanocrystals (CNC)

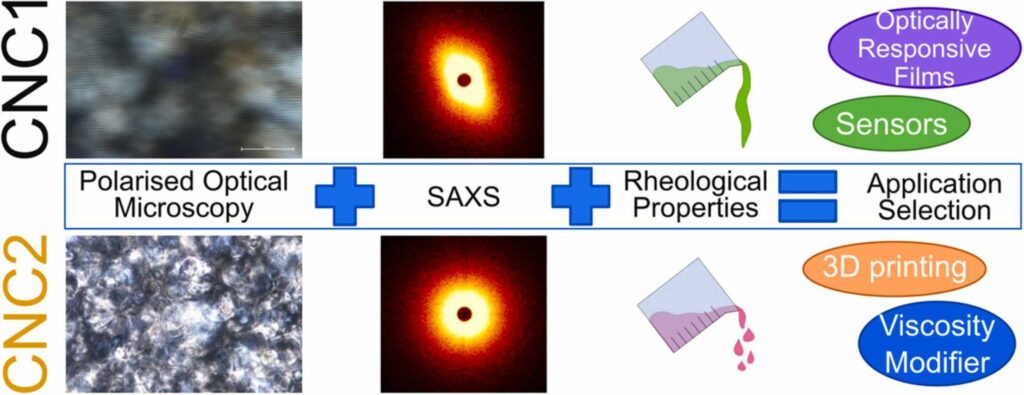

CNCs are highly crystalline, rod shaped particles with diameters of 5 nm to lengths of about 100 nm and a high surface charge. Due to these properties, CNCs can structure in suspensions to polarise light and create iridescent colour and have applications in optical devices and sensors. As the colour produce is dependent on the size and spacing between the crystals, characterisation of these materials is vital. We have developed a novel, application-based approached to characterisation using rheology and small angle x-ray scattering (SAXS) 1, 2 . We are also exploring how these interactions can be tuned to control the spacing and therefore the colour of CNC films and suspensions.

Investigation of packaging materials comprising nanocellulose and lignin particles

In this research project, we are investigating the effect of lignin particles on nanocellulose-based sheet materials, expecting them to be used as packaging. As both of these two components are plant-based, the obtained sheets are fully biodegradable and potentially contribute to reducing the use of plastic packaging, which is widely used in our society but can easily accumulate in the environment due to its non-biodegradability. The sheet materials are characterised from various viewpoints, such as mechanical properties, gas barrier properties, and anti-oxidant properties which are attractive for packaging and can be incorporated by lignin.

Engineering nanocellulose for packaging application

The use of eco-friendly bioplastics has become a viable solution to reduce the accumulation of petrochemical products in the biosphere and decrease microplastic contamination. Cellulose as the most abundant natural polymer can be a suitable replacement, especially in the packaging industry. Although cellulose in its nano dimension possesses great properties like high tensile strength and superior oxygen barrier properties, it still requires improvement to compete with its fossil-based counterparts. In my research, we aimed for physical and chemical modification of CNCs to tailor their film properties, opening up new applications as a highly performing barrier.

Cellulose nanofibres as potential biopolymer substitutes

Global trends, such as the accumulation of plastic waste and debris, climate change, and the depletion of fossil fuels have resulted in extensive pressure on numerous industries to shift from synthetic polymers to bio-based materials and composites. In addition, nanocellulose has been rigorously studied due to its high strength and stiffness, low density, dimensional stability, and our ability to modify its surface chemistry. As a result, this research will investigate the applications of cellulose-based nanomaterials to form advanced and novel composites to complement synthetic polymers for different applications. We will focus on the food packaging industry, where paper is widely used, especially as base material. One of the most stringent requirements for food packaging is inhibiting the transport of water vapour and oxygen gas. Due to the porous nature of paper, modifications, such as surface coating, are essential to meet these requirements. The research objectives of this project are:

- Develop a fundamental understanding on the water vapour and oxygen transport in non-chemically modified CNF films

- Manipulate the film preparation methods to further cement the potential of spray-coating as an industrial technology

- Provide a thorough and in-depth characterisation of different CNF feed types to establish novel characterisation methods and link the feed properties to the produced films

PUBLICATIONS

Cainglet, H.E., Tanner, J., Nasiri, N., Browne, C., Garnier, G. and Batchelor, W., 2023. Rapid cellulose nanomaterial characterisation by rheology. Cellulose, 30(8), pp.4971-4982.

Browne, C., Hertaeg, M.J., Mendoza, D.J., Naseri, M., Lin, M., Garnier, G. and Batchelor, W., 2023. Micropatterned cellulosic films to modulate paper wettability. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 656, p.130379.

Browne, C., Raghuwanshi, V.S., Lin, M., Garnier, G. and Batchelor, W., 2022. Characterisation of cellulose nanocrystals by rheology and small angle X-ray scattering (SAXS). Colloids and Surfaces A: Physicochemical and Engineering Aspects, 651, p.129532.

Browne, C., Lim, J.C., Sin, W.H., Garnier, G. and Batchelor, W., 2021. Influence of size and chemical additives on the fabrication of micropattern nanocellulose films. ACS Sustainable Chemistry & Engineering, 9(35), pp.11714-11723.

Raghuwanshi, V.S., Browne, C., Batchelor, W. and Garnier, G., 2023. Self-assembly of cellulose nanocrystals of different lengths. Journal of Colloid and Interface Science, 630, pp.249-259.

Browne, C., Garnier, G. and Batchelor, W., 2021. Moulding of micropatterned nanocellulose films and their application in fluid handling. Journal of Colloid and Interface Science, 587, pp.162-172.