Sustainable materials have become an important area of research in the search for alternative solutions to traditional petrochemical-based products. One specific research focus is the development of sustainable materials to replace olefins, which are commonly used in the production of plastics, synthetic fibres, composites, and other materials. The goal of this research is to find alternative materials that offer similar performance characteristics to olefins but are more environmentally friendly. One promising example of sustainable materials is vitrimers and organic glass. Vitrimers are a type of polymer that can be reshaped and reprocessed after being set, making them ideal for recycling and reuse. Organic glass, on the other hand, is made from renewable resources such as plants and can be produced using environmentally friendly methods. These materials have the potential to significantly reduce our reliance on non-renewable resources and help us transition towards a more sustainable future. In addition to the development of vitrimers and organic glass, there is ongoing research on novel advanced circular material concepts. These concepts aim to create materials that are fully circular, meaning they can be continuously recycled or biodegrade at the end of their useful life. Some examples of these concepts include bioplastics, self-healing materials, and the use of biological enzymes to polymerise and also break down materials. These innovative materials could revolutionize the way we produce and consume materials, leading to a more sustainable and circular economy.

RESEARCH PROJECTS

Vitrimers

Our research focuses on exploring the intricate world of vitrimer formulations and their remarkable properties. Through an extensive examination of off-stoichiometry mixtures with varying [epoxy]/[acyl] ratios, we investigate the dynamics of thermomechanical behaviour. Utilizing the catalytic properties of 1,5,7-triazabicyclo [4.4.0]dec-5-ene (TBD), we aim to achieve tunable material characteristics, such as stiffness, flowability, and insolubility. We discover that the network structure remains intact across different [epoxy]/[acyl] ratios. Notably, within the epoxy to acyl ratio range of 1:1 to 1:0.75, the material exhibits full flowability and stress relaxation under thermal stimulation, accompanied by increased viscosity and a consistent activation energy. Furthermore, our investigation reveals a gradual transition from vitrimer to non-exchangeable crosslinked materials beyond a stoichiometry of 1:0.6.

Our findings highlight the remarkable tunability of vitrimer formulations, enabling tailored thermomechanical properties without altering the chemical composition or manufacturing processes.

Figure 1: Polymer Chemistry covers with image showing the shape morphing, and self-healing capability of our tunable vitrimers.

Lipase-catalysed vitrimers

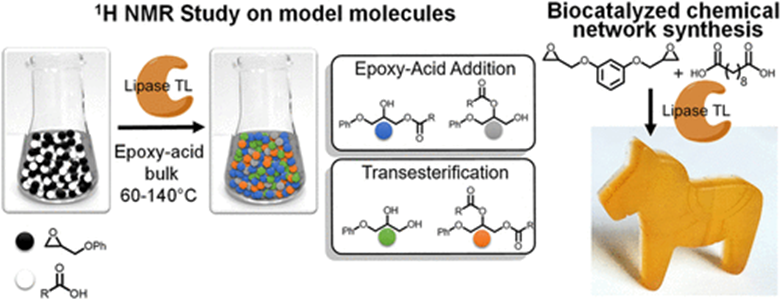

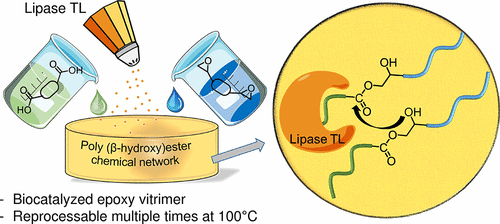

Through a fully bio-catalysed process, we have investigated the preparation and reprocessing of epoxy vitrimer materials, with lipase enzymes promoting network formation and exchange reactions. Binary phase diagrams are utilised to overcome limitations imposed by low curing temperatures (<100 °C) while protecting the enzyme. Suitable diacid/diepoxide monomer compositions are selected to prevent phase separation or sedimentation. Lipase TL, embedded within the chemical network, efficiently catalyses transesterification reactions, as demonstrated by multiple stress relaxation experiments conducted at 70-100 °C, resulting in complete recovery of mechanical strength even after several reprocessing assays (up to 3 times).

These transesterification vitrimers offer an alternative to classical catalysis methods, allowing for complete stress relaxation at lower temperatures compared to traditional organocatalysts like triazabicyclodecene.

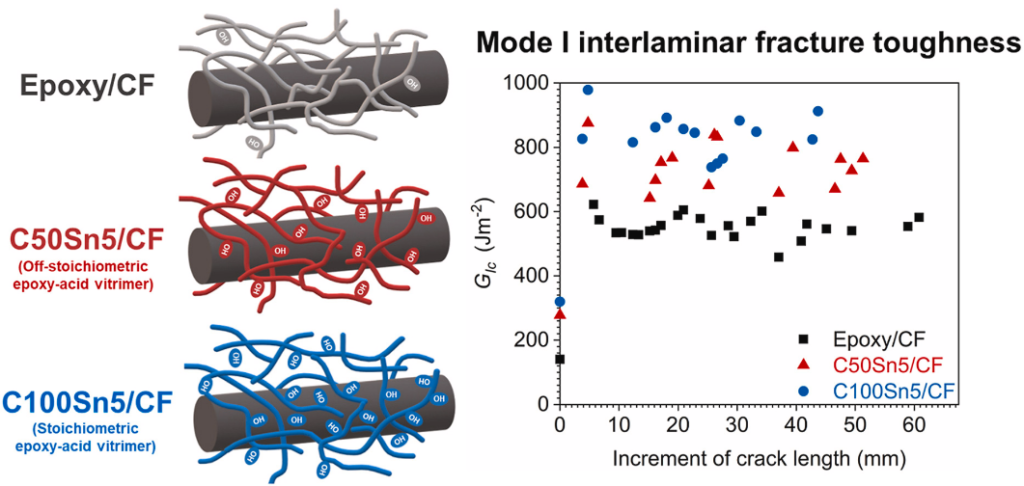

Carbon Fibre Reinforced Vitrimers

Our study focuses on assessing the interlaminar properties of carbon fibre reinforced polymer (CFRP) composites based on epoxy-dicarboxylic acid vitrimers with different epoxy:acid ratios. The results demonstrate remarkable stiffness and flexural strength in the vitrimer laminates, comparable to traditional CFRP composites. Moreover, the vitrimer composites exhibit superior interlaminar fracture toughness, surpassing standard epoxy laminates in terms of fracture energy at both initiation and propagation stages. These findings hold significant promise for advancing vitrimer CFRP composites and their potential applications.

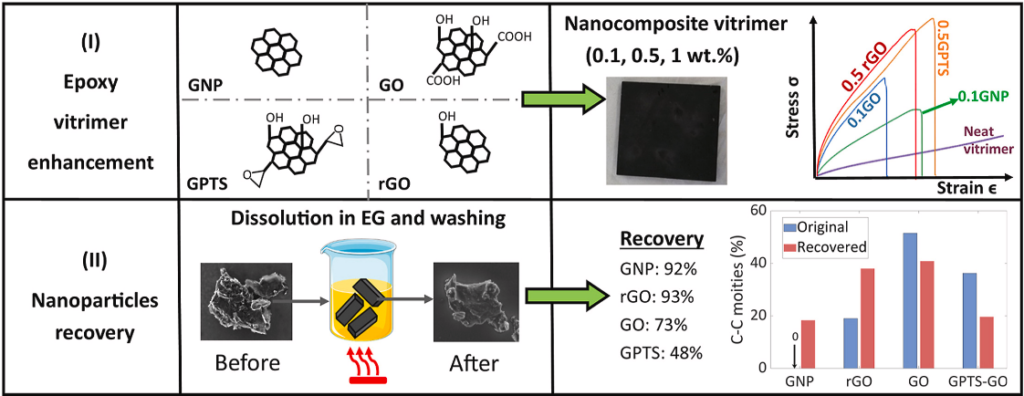

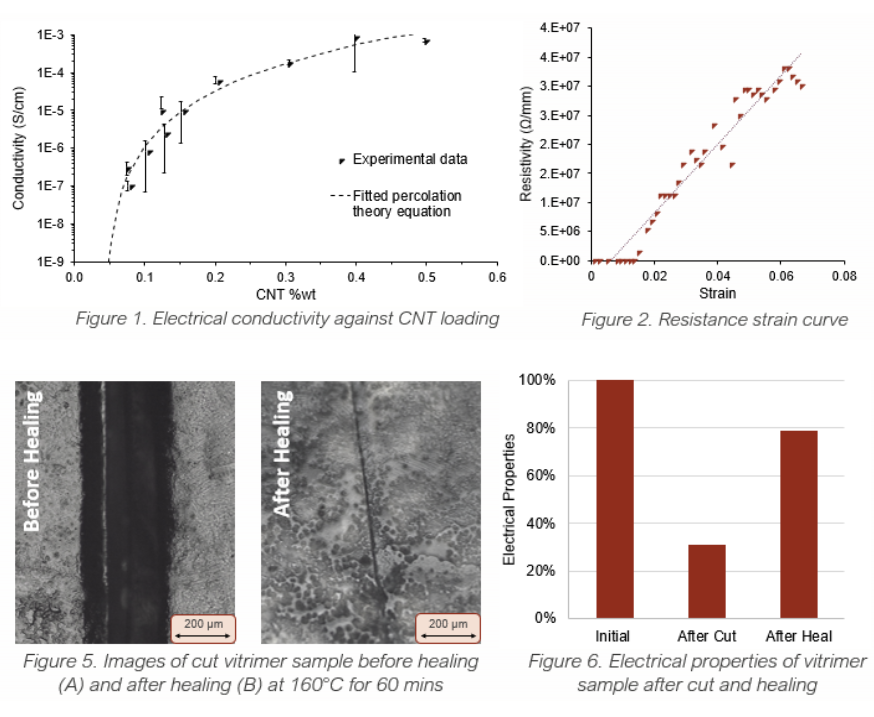

Graphene Enhanced Vitrimers

This study explores the addition of graphene nanoplatelets (GNP), graphene oxide (GO), reduced graphene oxide (rGO), and silane-bearing epoxy functionalized graphene nanoplatelets (GPTS-GO) to the vitrimer matrix. The integration of functionalized nanoparticles not only enhances tensile mechanical properties and promotes complete relaxation but also imparts sensing and self-healing capabilities to the material. Furthermore, the unique properties of epoxy vitrimers allow for the recovery of these nanoparticles through a dissolution/washing method, enabling their separation from the polymer matrix.

These findings highlight the immense potential of graphitic nanoparticle-enhanced epoxy vitrimers in the development of soft materials with multifunctionality, including sensing, self-healing, and recyclability, making them highly promising for applications in robotics and smart skin.

PUBLICATIONS

[1] Bakkali-Hassani, C.; Edera, P.; Lagenbach, J.; Poutrel, Q.; Norvez, S.; Gresil, M.; Tournilhac, F.; “Epoxy vitrimer materials by lipase-catalysed network formation and exchange reactions”, ACS Macro Letters, 12,3, 2023. https://doi.org/10.1021/acsmacrolett.2c00715

[2] Kumar, A.; Gresil, M.; Connal L.A.; “Dynamic elastomers based on bio-derived crosslinker”, Journal of Polymer Science, 2023. https://doi.org/10.1002/pol.20230005

[3] Tangthana-umrung, K.; Gresil, M.; “Interlaminar fracture toughness behaviour of carbon fibre reinforced polymer with epoxy-dicarboxylic acid vitrimer matrix”, Composites Communications, 32, 2022. https://doi.org/10.1016/j.coco.2022.101182

[4] Bakkali-Hassani, C.; Poutrel, Q-A.; Langenbach, J.; Chappuis, S.; Blaker, J.J.; Gresil, M.; Tournilhac, F.; “Lipase catalyse epoxy-acid addition and transesterification: model molecules study and network build-up from biobased monomers”, Biomacromolecules, 22(11), 4544-4551, 2021. https://doi.org/10.1021/acs.biomac.1c00820

[5] Poutrel, Q-A.; Baghdadi, Y.; Souvignet, A.; Gresil, M.; “Graphene functionalisation: preserving vitrimer properties towards nanoparticles recovery via mild dissolution”, Composites Science and Technology, Vol 216, 2021. https://doi.org/10.1016/j.compscitech.2021.109072

[6] Tangthana-umrung, K.; Poutrel, Q-A.; Gresil, M.; “Epoxy homopolymerisation as a tool to tune thermo-mechanical properties and fracture toughness of vitrimer”, Macromolecules, 54(18):8393-8406, 2021. https://doi.org/10.1021/acs.macromol.1c00861

[7] Poutrel, Q-A.; Blaker, J.J.; Soutis, C.; Tournilhac, F.; Gresil, M.; “Dicarboxylic acid-epoxy vitrimers: influence of the off-stoichiometric acid content on cure reactions and thermo-mechanical properties”, Polymer Chemistry, 11 (33), 2020. https://doi.org/10.1039/D0PY00342E